Shea Concrete-ICT partnership paying dividends for Shea’s quality control focus

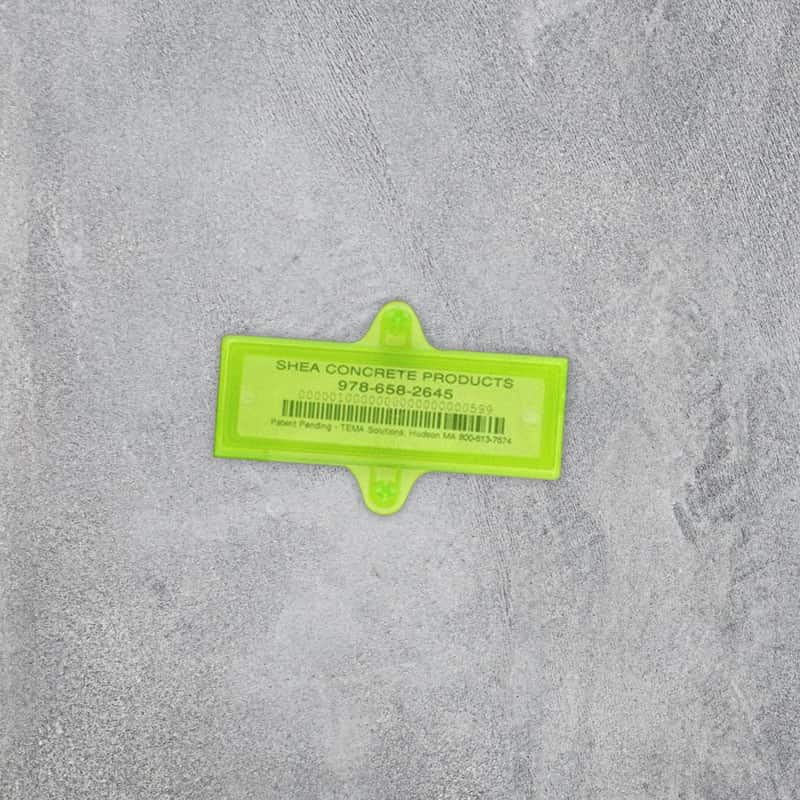

And for good reason. Burns and the rest of Shea Concrete Products has a leg up on the precast concrete industry thanks to International Coding Technologies (ICT) and its QC tracking system. The system tracks QC using scanners and ICT’s “Cast-A-Code™” radio frequency identification tags (RFID). The Cast-A-Code™ RFID tags were first developed in 2006-07 and built to electronically store information while the tag is embedded in the object. It transfers data with the focus of automatically identifying and tracking the object. Unlike barcodes, these tags are ruggedized and designed to sustain heavy duty environments.

For the past five years, Shea has utilized RFID tags to track each of its precast concrete products before and after the pouring process. The wireless system has done what it was intended to — reduce labor costs and increase production efficiency.

“It’s all for quality control purposes,” said Burns. “It’s definitely helped us out and you know exactly what you’re getting for a product. There’s no second guessing with this inventory practice. I love technology. Whatever we can do to make things faster and more efficient, I’m all about it.”

ICT, based in Topsfield, MA, regularly works with Shea to test new products as it continues to build a global presence. Primarily focused on the precast concrete industry, ICT also designs, develops, and implements tracking systems for steel-fabricated products. Company founder and President Tom Tilson believes Shea’s high ranking in QC is partly due to its electronic inventory practice.

“We’ve known the Shea crew for quite a while. (Manager) Greg Stratis is a forward-thinking guy and gets how to leverage the business,” Tilson said. “As a software developer, it’s our job to offer a value proposition to the precaster.”

Burns says it won’t be long before Shea switches over to Idencia, ICT’s new cloud-based product, to log its expanding inventory. Benefits include lifecycle tracking and increased product visibility.

“If we still logged everything through paper, we would lose space and risk documents getting misplaced. With RFID technology, we have everything we need when we need it,” said Burns. “So no, I don’t think we are switching to paper any time soon.”